| NAVAL ORDNANCE AND GUNNERY, VOLUME 1 CHAPTER 6 GUN BARRELS AND INTERIOR BALLISTICS |

| HOME INDEX Chapter 6 Gun Barrels and Interior Ballistics A. Introduction B. Elements of gun design and maintenance C. Interior ballistics D. Erosion E. New developments in gun design |

| D. Erosion 6D1. Causes of erosion The deterioration and wearing away of the bore surface by use is known as erosion. This effect is not the direct result of friction caused by the projectile in its movement down the bore. There is some uncertainty about the exact process by which the interior of a gun wears away, but it is generally agreed that the following are the principal causes: 1. The inner surface becomes intensely heated in firing, and the rush of hot gases across this hot metal has a scouring effect. 2. The hot powder gases react with the metal, changing the carbon content on the surface of the bore. Since this surface is designed with an optimum carbon content, any change results in a weakening of the metal. 3. The alternation of intense heat and rapid cooling affects the temper of the metal. 4. The explosion gases are forced into and out of the pores in the metal surface as they open and close during the expansion and contraction which accompanies such drastic temperature changes. 5. Heat cracks may develop. 6. Gases escaping around the projectile act as high-velocity jets, scouring the bore and causing damage, especially where there are heat cracks. 6D2. Effects of erosion Two fundamental facts of erosion are (1) that it is always greatest at the origin of rifling, and (2) that the tops of the lands wear away faster than do the bottoms of the grooves. Enlargement at the origin of rifling, in bag guns and guns using semifixed ammunition, tends to permit the projectile to seat farther and farther toward the muzzle. This reduces the density of loading and therefore the muzzle velocity. To avoid this, there is a lip of slightly greater diameter at the base of the rotating band which tends to engage the forcing cone more nearly at the same point at every loading, regardless of gun wear. Naturally, this applies only to bag and semifixed ammunition, where the projectile is not positioned by the case. In all guns, however, erosion at the origin of riffing permits gas to escape around the projectile, and this in turn increases erosion. As the lands wear, not only does more gas escape around the projectile but the rifling engraves the band less deeply, reducing materially both the initial forcing pressure and the resistance of the projectile to the gas pressure. The effect is a material drop in muzzle velocity. 6D3. Control of erosion All erosion factors are related to (1) the temperature of the expanding gases and (2) the duration of their confinement in the bore. So, larger guns, with their slower powders and longer barrels, suffer more erosion per round fired than smaller guns, but the higher firing rate of the lesser guns offsets this, because it permits less cooling time between rounds. Chromium plating of gun bores has reduced the effects of erosion, and it may be possible that in the future the use of molybdenum in this fashion will make for even better erosion resistance. Some smaller guns are cooled by water jackets around the barrels, and experiments are under way on introducing a coolant between the tubes and the liners of larger guns. Also under development are cooler propellants. Any development that reduces the heat of explosion will aid in erosion control and, inasmuch as excessive erosion imposes much of the present limitation upon muzzle velocity, temperature reduction appears to be a most practical approach to more effective gunnery. 6D4. Gun life Erosion, however carefully controlled, eventually terminates gun life. Though, with the exception of the larger turret installations, regunning is relatively simple, it cannot be done under combat conditions. Therefore, the duration of the effectiveness of a gun is of paramount importance. Symptoms of the end of serviceability are: (1) loss of accuracy, (2) loss of velocity, and (3) erratic fuze actions. Naturally, a gun that does not hit its targets is no longer useful; neither is one of inadequate range and armor-piercing capacity, both of which result from velocity loss. Erratic fuze action not only undermines effectiveness but can endanger friendly personnel. Any of these conditions can take place when the rifling no longer imparts adequate rotational velocity to stabilize the projectile in flight. In small arms, this effect can be seen when tracers are used, and a barrel should be replaced when erratic flight is observed. With larger guns, however, it is important that replacements be made before the effectiveness is seriously reduced. Up to the present, relining guns has been a naval shipyard operation, but recent experiments indicate that it may soon be possible to use a loose liner with as much as 0.0 10 inch between it and the tube. This will make it possible to regun aboard ship under active service conditions. With expendable liners, much higher muzzle velocities with their increased erosion would become acceptable. |

|

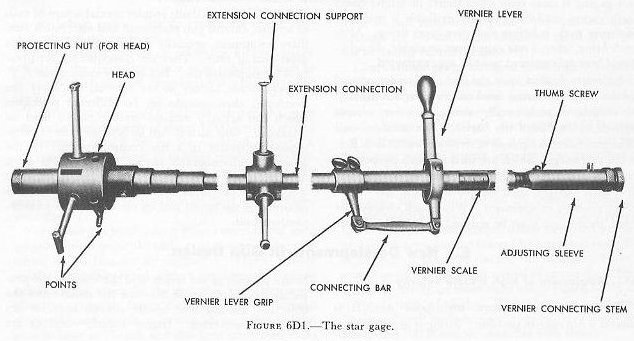

| 6D5. Erosion measurement There are, for each class of gun, curves furnished to ships showing relationship between the enlargement of the bore and the initial velocity to be expected from the gun. Thus if the actual diameter is frequently checked, velocity loss becomes predictable, proper allowance for it can be made in aiming, and, of at least equal importance, barrels or liners may be replaced before their performance becomes noticeably erratic. In some minor-caliber guns, measurement of bore enlargement is made at the origin of rifling only. This is done with a wear gage, which is a truncated cone that can be inserted directly in the breech. In larger guns, erosion is measured at several points in the bore with a star gage. This is a simple device, consisting basically of a hollow staff with a head at one end and a handle at the other. By means of the staff, the head can be inserted in the bore to the desired point. Three removable points, the length of which varies with the caliber of the gun to be measured, are carried in sockets spaced radially 120° apart in the head. The sockets are pressed inward upon a cone by spiral springs and move inward or outward, at right angles to the staff, as the cone, activated by a threaded rod which the hollow staff contains, is advanced or retracted. A vernier on the handle end of the staff measures this inward and outward movement of the points in thousandths of an inch. Before use, the star gage is calibrated by inserting the points into a standard ring, accurately machined to the designed bore diameter of the gun, and setting the vernier at zero. Then, upon insertion into the bore, vernier readings directly measure bore enlargement. As a rule, two readings, 180 degrees apart, are taken at each point of the bore to be measured. Of these measurements, that taken immediately forward of the origin of rifling is the most important. It has been found that muzzle velocity loss is a function of bore enlargement at this point, and tables or graphs, such as those illustrated in volume 2, are predicated upon it. Specimen curves (for 5”/38 guns Mk 12 and mods) used in figuring equivalent service rounds and velocity loss are illustrated in appendix B. One curve shows equivalent service rounds plotted against measured bore enlargement (in thousandths of an inch) at the origin of rifling. The other curve shows directly velocity loss (from the nominal standard service value of 2,600 fps) as plotted against bore enlargement at the same point. Thus, from the measurement of bore enlargement, it is possible with these curves to determine equivalent service rounds fired, and velocity loss in feet per second. 6D6. Velocity loss estimation Star gages are not carried on combatant ships, and star gaging is done only when shore- or tender-based facilities are available, however desirable it might be in theory to do it before and after every firing. After each firing, when a star gage is not available, the additional bore enlargement must be approximated. Estimates depend upon the fact that, under normal conditions, each round fired causes a certain amount of erosion, experimentally determined for various periods in the life of the barrel. The standard unit of measurement is equivalent service rounds (E. S. R.). Reduced charges, which are used for such purposes as gunnery practice, have less effect than service charges. Increased charges, used for proving guns, have more effect on bore enlargement. When such charges are fired, their effect must be reduced to E. S. R.’s before the curves can be used. For instance, it has been determined that a reduced 1,200 fs charge will cause only one-sixth the erosion of a full 2,600 fs charge. Consequently, for computation purposes, six such rounds would be regarded as one E. S. R. The legend accompanying the graphs gives the proper method of using them. (See appendix B.) Other corrections are required when firing certain indexes of powder, but such information is included in the same Bureau of Ordnance publications as the curves. Without periodic star gaging, the equivalent-rounds procedure would not be accurate, mainly because the typical curves take no account of the rate of fire. Rounds fired with very short cooling intervals between cause much greater erosion than the same number of rounds fired at normal intervals. For practical gunnery, however, the curves are considered sufficiently reliable for use, if no better data can be obtained. 6D7. Improved methods of measuring I. V. At proving grounds gun projectile velocity is measured by a device called a chronograph. In one (older) type the projectile cuts wires when it passes through two successive screens located in the trajectory at known ranges, and the exact time of each passage is recorded. This yields the projectile velocity between the screens, and from this I. V. can be reckoned. In a more recent type, the projectile passes through two magnetic coils in succession, and the induced impulses, amplified, cause sparks to pass through a rapidly moving tape. From this the elapsed time and then the I. V. can be worked out. Both of these methods require special setups of coils or screens, careful gun placement and aim, much auxiliary equipment, specially skilled technicians, and a good deal of time. They are consequently not practical for shipboard use. But because erosion and I. V. are significant factors in fire control, the Navy has developed chronographs on far different principles which can actually measure service rounds fired on shipboard. One such design incorporates the velocity-measuring device in a fire control system. In the other, the chronograph device (which works on a different principle from those already mentioned, since it measures projectile velocity in the gun bore) is mounted in the barrel and on the carriage as an independent unit. |