| GENE SLOVER'S US NAVY FIRE CONTROL PAGES NAVAL ORDNANCE AND GUNNERY VOLUME 2, FIRE CONTROL CHAPTER 27 TORPEDO FIRE CONTROL |

| HOME INDEX Chapter 27 Torpedo fire control A. General B. Destroyer torpedo fire control problem C. Destroyer torpedo fire control system D. CIC's function in the radar-aim torpedo attack |

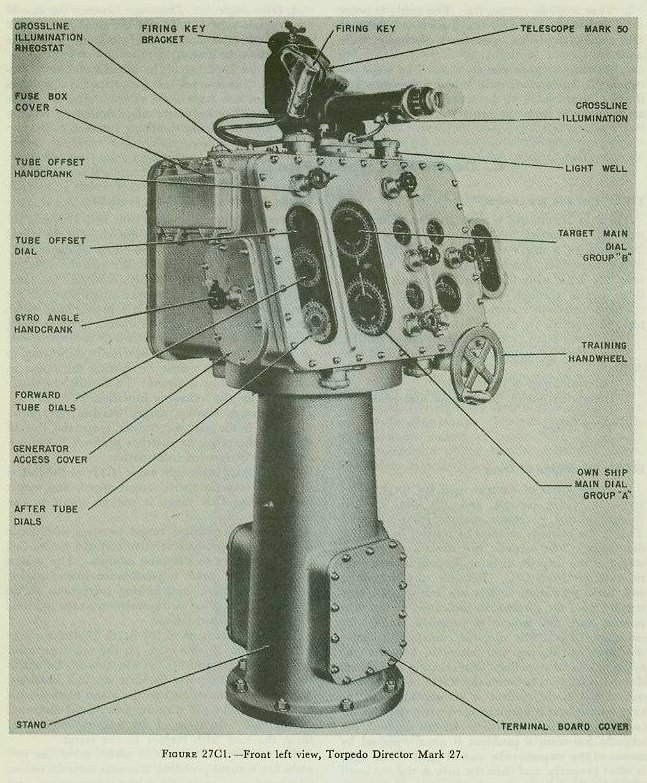

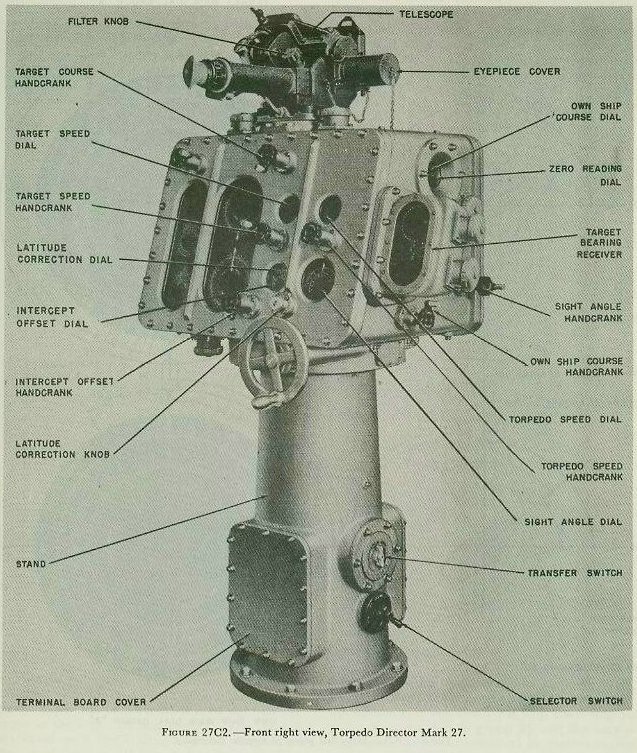

| C. Destroyer Torpedo Fire Control System 27C1. Torpedo fire control Torpedo fire control is a subdivision of fire control and comprises the system of directing the launching of a ship’s torpedoes. It includes material, personnel, communications, and organization. It deals with the launching of a relatively slow missile through the water on the correct course to intercept a target. The functions of torpedo fire control are as follows: 1. Determination or estimation of target motion. 2. Selection of torpedo settings for speed and depth. 3. Determination of sight angle. 4. Determination of spread plan and offsets. 5. Aiming. 6. Tube laying. 7. Firing. 27C2. The control of firing The two kinds of control used for torpedo fire are: (1) bridge control, and (2) local control. Bridge control is remote control from directors. This is the primary method of control on modern destroyers. The torpedo fire control problem is solved at the torpedo director, in conjunction with information from CIC. Relative torpedo course and basic gyro-angle orders are transmitted electrically from the director to indicators at the tube mount, and the mount is properly trained by matching dials. The director continues to solve the problem during the intervals between the firing of several torpedoes, thus creating a small additional variation between the tracks of the several torpedoes. Local control is accomplished at the tube mount, and is normally used when the director control system is inoperative. In this method, the torpedo fire control problem is usually solved by means of the torpedo-tube mount sight. The sight is offset properly, and then the tube is trained until the sight is on the point of aim. Spreads may be fired by setting spread angles on the torpedo gyros or by varying the: point of aim. 27C3. The Torpedo Director Mark 27 Most destroyers are fitted with two Torpedo Directors Mark 27 mounted on the wings of the signal bridge, one on each side; and either of these directors may control the fire of the single centerline quintuple-tube mount usually installed. As mentioned in chapter 21, proper alignment of the torpedo fire control system is a prerequisite to an accurate solution of the problem. The primary function of the torpedo director is to control one or more tube mounts by electrically indicating to them the torpedo course for hitting the target at which the director is aimed. To do this, the director performs the following functions: 1. Measures relative target bearing (Br) automatically if the director trainer keeps the line of sight on the target or matches pointers in accordance with designated information. 2. Computes basic sight angle (D) from the initial inputs of torpedo speed, target speed, and target angle. (Note that range is not an input to the director.) 3. Combines relative target bearing with basic sight angle to produce relative torpedo course Car for transmission to the tube mounts. The design of the director makes it possible for spread angles, latitude correction, and aiming corrections to be applied to Car prior to transmission to the mounts, as will be described later. The principal parts of the Mark 27 director are: (1) the stand, (2) the case, (3) the telescope unit. See figures 27C1 and 27C2. The stand is bolted to the deck and supports the case on ball bearings. A training circle secured to the stand meshes with a gear driven by the training handwheel mounted on the case. Rotation of the training handwheel turns the case with respect to the stand. |

|

|

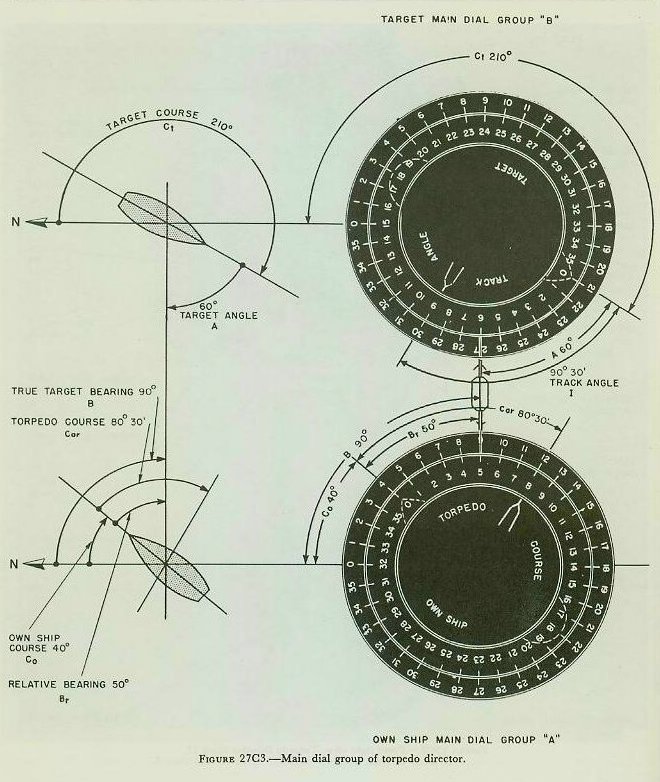

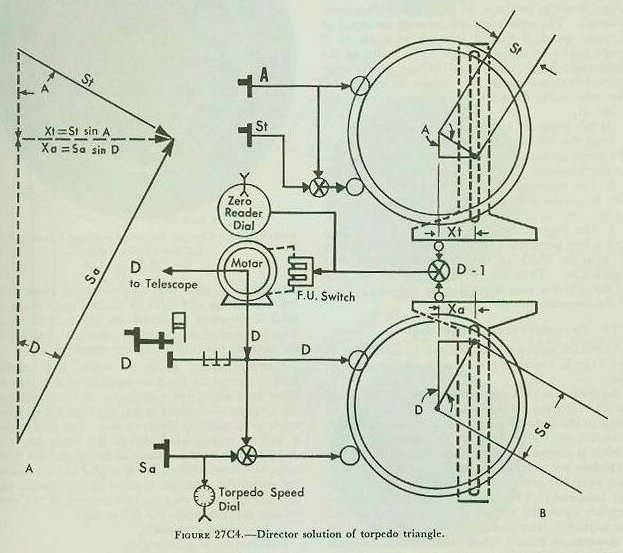

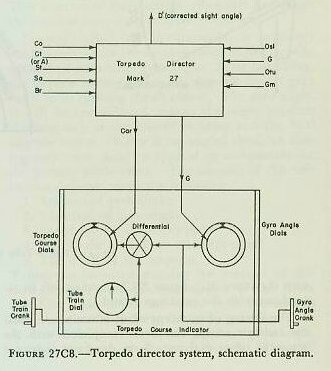

| The case houses the units which solve the torpedo fire control problem, transmit torpedo course (Car) and gyro angle (G) to the tube mounts, and receive own ship’s course (Co) from the gyro compass. The knobs for hand inputs and all dials are attached to the case. All inputs are manual except own ship’s course (Co), and if the automatic transmission fails, the Co knob can be used to introduce this value manually. The telescope unit is normally positioned by a servo follow-up motor within the case. This may also be done manually with the sight-angle crank, on the right side of the case. The Telescope Mark 50 consists of a tiltable mirror and fixed-prism telescope mounted on a pivot. The tiltable mirror makes it possible to hold the line of sight on the target as the ship rolls and pitches. The pivot is supported on a ball-bearing assembly attached to the top of the case. It is geared to the computing mechanism within the case and is automatically turned with respect to the case through the computed sight angle. 27C4. The director solution In solving the torpedo problem by a director the initial set-up is made by (1) making manual settings of St, Sa, Gt or A, (and of Co if not received electrically) (2) receiving own ship’s course Co electrically, and (3) keeping the telescope line of sight on the target. The introduction of these settings will set up on the main dial group of the director a picture such as shown in figure 27C3. In each dial group the outer ring is a compass ring, the middle ring represents the ship (own ship in group A, target ship in group B), and the central ring represents the torpedo track in relation to own ship and target. The director solves for sight angle by the principle of equal deflections, in which torpedo deflection (Xa) must equal target deflection (Xt). Then, since Xt=St sin A and Xa=Sa sin D, sin D equals St sin A/Sa Figure 27C4 (A) shows the elements of the firing-ship-target set-up and figure 27C4 (B) shows how two component solvers are used to solve for D. In this elementary solution, gyro angle, latitude correction, intercept and tube offsets, and spread angles are not considered. The target solver, from inputs of target course, target speed, own-ship course, and relative target bearing, produces Xt (target deflection component). The sight-angle solver, with an input of torpedo speed, is rotated through an angle of D (sight angle) by the sight-angle servo motor or the sight-angle hand crank, until its output, Xa (torpedo deflection) equals Xt. When Xt equals Xa, the zero-reader dials in the torpedo director are matched. At this point the following relationships exist: Since the telescope LOS is directed at the target, the angle measured clockwise from the ship’s bow to the telescope axis is relative target bearing Br. 2. The telescope unit has been offset from the line perpendicular to the face of the director case by the amount of basic sight angle D. 3. The angle between the bow of the firing ship and a line perpendicular to the face of the case is Br plus D, which (if corrections be disregarded) equals Car. Thus the perpendicular to the face of the director case is parallel to the mean track of the torpedoes. |

|

|

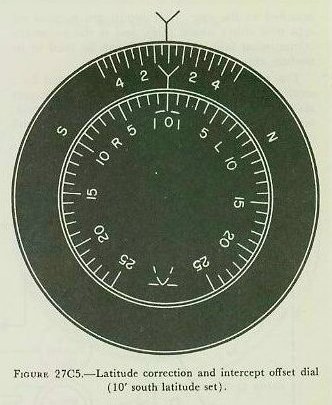

| 27C5. Corrections to basic sight angle Corrected sight angle is obtained by modifying D for latitude correction, Gm, and intercept offset, Osi. Latitude correction, set manually, compensates for the inherent tendency of the torpedo gyro to creep to the right in north and to the left in south latitudes, due to the rotation of the earth. (No correction is necessary unless the latitude in which the torpedoes are to be fired differs from that at which they were last proved or at which their gyros were last balanced.) The magnitude of the correction depends upon the length of the torpedo run and the latitude. The amount of correction necessary is determined from a “click table” which indicates the number of clicks of the latitude-correction knob required to correct for the latitude in question. Each click moves the dial 10 minutes. Figure 27C5 shows the latitude correction and intercept offset dial. The outer ring is used for latitude settings and the inner dial for setting intercept offset. In the figure, 10’ south latitude correction has been set by rotating the outer ring, causing the S portion to lie opposite the fixed index. The intercept offset dial does not move while making this setting and must be rotated until the zero mark is opposite the index on the latitude ring. This rotation of the intercept offset dial introduces the latitude correction into the director. |

|

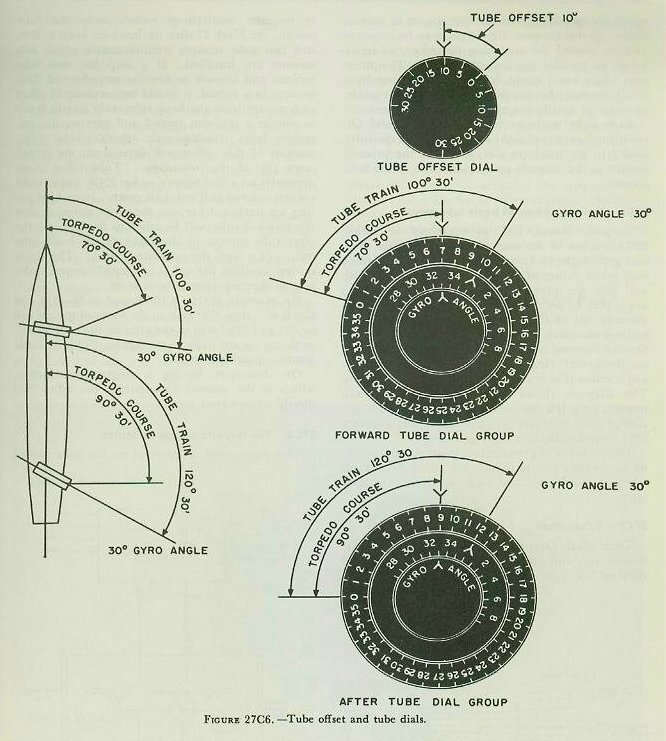

| Intercept offset, set in manually, is primarily used to correct for the turning circle of the torpedo when fired with large gyro angle. After launching, the torpedo turns right or left through the set gyro angle to its running (final) course. The gyro angle, it will be remembered, equals the angle between the tube axis at the instant of firing and the final torpedo course. When firing angled shots, an aiming correction must be applied to compensate for the turning circle effect. The amount of this correction depends upon the following: 1. Amount of gyro angle. 2. Direction of gyro angle. 3. Speed setting of the torpedo. 4. Run of the torpedo to intercept point. 5. The mark of the torpedo. Tables are provided showing the amount of this correction for various combinations of the above variables. The correction taken from the table is to be applied by turning the intercept offset knob in the same direction as the applied gyro angle, through the amount of the correction. This will turn the inner dial, figure 27C5, right or left in accordance with the markings R and L. The setting of intercept offset is not made until the latitude setting has been completed with the intercept offset dial zeroed on the fixed index of the latitude ring. If this procedure were not followed, erroneous inputs would result. Another use of the intercept offset dial is to provide a small variation in sight angle to compensate for expected target maneuvers in attempting to avoid the torpedoes. In the case shown in various figures in this chapter, the target may be expected to turn toward the oncoming torpedoes, in an attempt to parallel the torpedo tracks. The intercept offset knob could be used to decrease by a small amount the computed value of sight angle, in order to nullify the effect of this maneuver. Basic sight angle as corrected by Gm and Osi constitutes corrected sight angle, D’. This quantity, added to Br, produces Car, which is the primary output to the torpedo course indicator at the tube mount. 27C6. Determination of basic tube train Torpedo course, Car, as explained in article 27B3 consists of the sum of basic tube train, Bur, and gyro angle, G. Control personnel on the bridge may select values of Bur and G which, combined, will give the proper value of Car, because gyro angle may be set manually by means of a crank in the left side of the director case. In making the settings the dials shown in figure 27C6 are used. On the forward tube dial group, gyro angle is set on the center ring dial opposite the fixed gyro angle index (the reading shown being 330 degrees). The diagram shows how torpedoes from both mounts turn left 30° to their final course. A setting of 360° indicates zero gyro-angle set; a setting 030° would indicate a right gyro angle. The set value of gyro angle is transmitted directly to the torpedo course indicator at the tube mount, where it is indicated and used as will be explained later. |

|

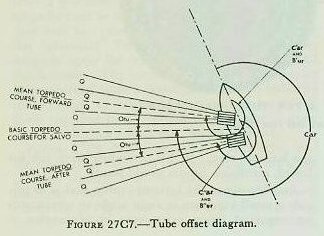

| 27C7. Tube offset Tube offset, Otu, is the angle between the tube-mount axis and basic tube train (Bur), measured right or left from Bur. Although modern destroyer torpedo installations include only one tube mount, the Mark 27 director has been built to control two tube mounts simultaneously where two mounts are installed. If a ship has two tube mounts and intends to fire the torpedoes of both mounts in a spread, it would be necessary to offset each mount from the basic tube train Bur in order to obtain a uniform spread and prevent the torpedoes from crossing each other’s tracks. The amount of tube offset will depend on the spread angle (Q) of the torpedoes. Tube offset is set manually on a dial (shown in fig. 27C6, upper right corner) colored half red, half green. In making setting for starboard fire, use the green sector, so that the forward tube will be offset to the left and the after tube mount to the right of the basic tube train. (To port, the opposite is true.) The single setting modifies the value of torpedo course order sent to the respective tube mounts. For example, if Otu is 10° (based on Q==4°), and Car is 80°, then C’ar sent to the forward mount will be 70° and C”ar sent to the after mount will be 90°, as shown on the dials in the figure. (This example assumes quintuple tubes.) On destroyers having a single tube mount, which is the normal installation, the offset dial should always read zero. |

|

|

|

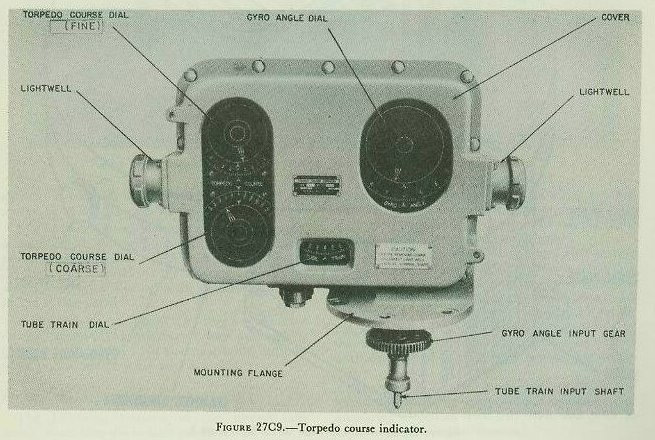

| 27C8. The torpedo course indicator This instrument is installed on the tube mount and indicates the following values: 1. Actual tube-mount train. 2. Gyro angle ordered. 3. Gyro angle set. 4. Torpedo course ordered. 5. Torpedo course set. Quantities 2 and 3 are compared on a follow-the-pointer dial. Quantities 4 and 5 are compared on zero-reader and follow-the-pointer dials. Referring to figure 27C9, torpedo course, received electrically from the director, positions the inner dial of the torpedo-course dials at the left. Gyro-angle order, received electrically from the director, likewise positions the inner dial of the gyro-angle dial group at the right. Matching gyro-angle order is accomplished by rotating the gyro-angle hand crank on the mount; this action also sets the gyro angle on the torpedo gyros to agree with the value transmitted by the director. This setting also goes through a differential, partially positioning the outer (ring) dial of the torpedo-course dial group. As the mount is trained, actual tube train from the auxiliary training rack positions the tube-train dial and also goes through the differential to match the torpedo-course dials. Thus torpedo course for torpedoes fired from a tube mount equals mount train plus gyro angle. The tube-train dial is painted red in the danger sectors, and yellow in the adjacent 10° sectors, providing the tube trainer with suitable warning. If, after matching torpedo-course dials, he observes the tube train dial to be “in the red,” he must train clear of the danger sector, which will cause the torpedo-course dials to become unmatched. He then orders the gyro setter to apply the necessary additional gyro angle to rematch the torpedo-course dials. This is known as “gyro-angling.” Intercept offset correction for this additional gyro angle will not, of course, be applied; but when it is imperative that torpedoes be fired without delay, it is thus possible to modify a director solution which would put the tube on a danger bearing. |

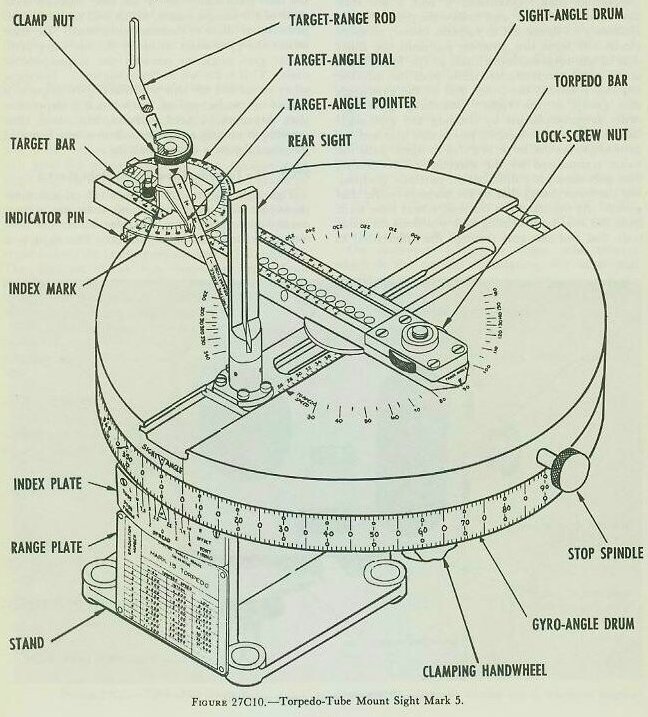

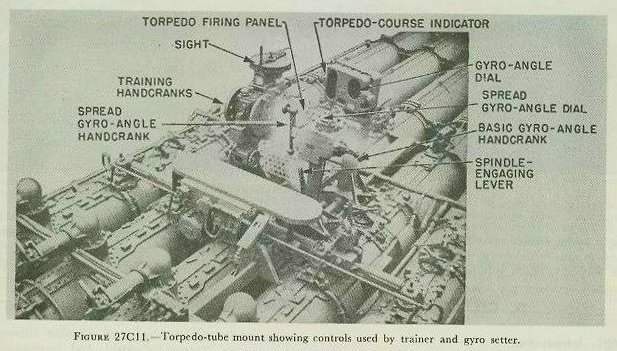

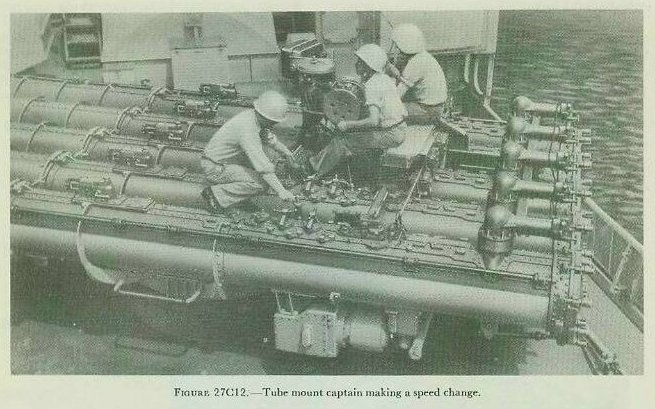

| 27C9. The Torpedo-Tube Mount Sight Mark 5 This sight, figure 27C10, installed on the tube-mount training handwheel stand, is for use in local control of torpedo fire. Its location on the tube mount is shown in figure 27C11. The sight is a combination director and aiming device and consists of two concentric rotatable plates. The upper plate carries pivoted and sliding bars which can be set to reproduce the speed triangle of torpedo fire from inputs of A, S, and Sa. These inputs offset the sight bar by the correct D. Then when the sight is aimed at the target, the mount is correctly trained to lead the target. Gyro angle may be introduced by rotating the lower plate to the desired G, moving the upper plate with it to introduce this further offset to the sight. When D is computed by the Mark 27 director, its value phoned to the mount, and the tube-mount sight used only for aiming, the control is called “local aim of bridge control.” In this use of the Mark 5 sight, the pivoting and sliding bars are not set up as previously described. Instead, the upper plate is rotated to the ordered D, offsetting the sight bar (line of sight) from the tube-mounts axis. 27C10. Torpedo firing and ready light system The purpose of this system is to provide electrical firing of each barrel, controlled from the bridge. The control features of the system are as follows: 1. The bridge firing panel. One bridge firing panel is installed near the director for each tube mount. It contains the tube-mount ready light and a selector switch for each barrel. 2. The mount firing panel. A mount firing panel is installed on the tube mount near the trainer’s position. It contains a switch which closes or opens all the firing circuits on the mount. When this switch is closed, it also lights the mount ready light in the bridge panel. 3. The firing key. There is a firing key mounted on the director. An auxiliary bridge key may be plugged in if needed. No electrical firing can take place unless one of these keys is closed. 27C11. The torpedo-tube mount The following features of the torpedo-tube mount enter into the control problem: 1. The gyro-setting mechanism. This permits setting both gyro angle (G) and spread angle (Q). The gyro spindle-engaging lever is moved to the IN position, causing a vertical spindle to extend through each barrel from the bottom and engage the gyro-setting mechanism of the torpedoes. The gyro-angle hand crank is rotated until the desired angle is indicated on the gyro dials. This sets the same gyro angle, G, on each torpedo, and this value appears on the torpedo-course indicator. Another hand crank, the spread-angle setting hand crank, is rotated until the desired spread angle (Q) is indicated on a dial on the hand-wheel pedestal. This produces different gyro settings on individual torpedoes, so that they will fan out from the center torpedo with a separation of Q degrees. 2. The depth-setting mechanism. This permits setting the depth at which the torpedoes are to run. The depth-setting socket lever is placed in the IN position, causing a vertical shaft, fitted with a socket on its end, to extend through each barrel from the top and. engage the depth-setting mechanisms of the torpedoes. The hand crank is then rotated until the desired depth setting is indicated on the dial. (Gyro-setting spindles and depth-setting socket levers must be in the out position when loading or unloading torpedoes from the tubes, and prior to launching, for obvious reasons.) 3. Torpedo speed setting. This is set by engaging a spring-loaded spindle in each barrel of the tube mount with the speed-setting mechanism of the torpedo. Each spindle is rotated by hand to the HIGH, INTERMEDIATE, or LOW position as indicated by the index pointer, and is then released. The spring will then automatically disengage the spindle from the torpedo speed-setting mechanism. |

|

|

|