| GENE SLOVER'S US NAVY PAGES NAVAL ORDNANCE AND GUNNERY VOLUME 1, NAVAL ORDNANCE CHAPTER 13 MINES |

| HOME INDEX MINES A. General B. Aircraft mines C. Mine Warefare |

| A. General 13A1. Naval mines defined There are two general classes of military mines: land mines, under Army cognizance, and sea mines, under Navy cognizance. This chapter is concerned with sea (or naval) mines only. Navy mines are thin-cased underwater weapons with a heavy load of high explosives-usually either HBX, HBX-1, or TNT. Mines are actuated when touched or closely approached by a ship. An actuation can have 1 of 4 results, as follows: 1. The mine, especially if it is one of the older types, may explode almost immediately. 2. The mine may explode after a short delay that gives the target ship time to reach a more vulnerable position. 3. The actuation may be registered by a ship-counting component that prevents explosion until a predetermined number of actuations have been counted. 4. In a controlled mine field, the actuation of a mine energizes indicating devices at a shore station, but does not result in an explosion unless a return signal is sent to the mine from shore. 13A2. Classes of naval mines Broad classification. All naval mines fall within 1 or the other of 2 broad classes-independent and controlled. All old mines and many new ones are the independent (sometimes called the automatic) type. Once planted and armed, the independent mines can be actuated by the presence of a ship, without any human intervention. They are incapable of discriminating between hostile and friendly vessels. Until they have been made harmless-either by incorporated self-destructive features or by sweeping-independent mines are a threat to all vessels approaching the area. In contrast to independent mines, controlled mines have an electrical system connecting them to a shore station. Signals from approaching or passing ships are transmitted to shore over this electrical system. Depending on the military situation, the personnel at the shore station may merely observe the signals, may detonate a given mine by answering its warning with a return signal, or may set the equipment to return the firing signal automatically. Other classification methods. The broad classification system described above is cut across by three other methods of classifying mines; namely by method of planting, by position after planting, and by type of firing mechanism. The paragraphs following will explain these three classification systems. 1. By method of planting. Mines may be laid from surface craft, from submarines, or from aircraft. When secrecy is not a prime consideration, mines may be planted from specially designed minelayers or from certain other surface craft. By working as a team, surface vessels can lay a large field in a short time. Controlled fields are planted by surface craft, as are many of the defensive fields containing independent mines. When secrecy is supremely important, submarines can carry mines great distances from home ports. Submarines may also launch mobile mines-usually called torpedo mines-into the fringes of established fields or into enemy-held waters. When extensive mining operations are to be conducted in enemy-held waters, when large defensive fields are to he replenished, or when shallow inland waterways are to be mined, aircraft planting is usually most efficient. The airplane has the advantages of speed and maneuverability, but it sometimes has the disadvantage of being easily seen and fired upon by the enemy. 2. By position after planting. When classified according to the position they assume in the water, mines fall again into three groups. These are bottom mines (formerly known as ground mines), moored mines, and drifting mines. Its large amount of negative buoyancy brings the bottom mine to rest on the ocean floor and keeps it there. Bottom mines are most effective in comparatively shallow waters. If a bottom mine is planted in very deep water, surface vessels may pass over it without actuating its firing mechanism, or, in event of an actuation, without suffering much damage. Of course a bottom mine planted in deep water may still be effective against submarines. Bottom mines are used in controlled fields, but are by no means limited to that use. The explosive charge and firing mechanism of a moored mine are housed in a positively buoyant case. A cable or chain, attached to a negatively buoyant anchor that rests on the sea bottom, holds the case at a predetermined depth beneath the surface. The drifting mine floats freely, at or near the surface. It has no anchoring device, and its buoyancy is approximately neutral. The depth at which this mine travels is determined by one of three methods: by suspending the mine from a small float, by incorporating a mechanical depth-control device, or by attaching a cable or chain that drags on the bottom in shallow water. 3. By type of firing mechanism. There are two main classes of mine-firing mechanisms: the contact type and the influence type. The influence type is the newer one. Each type is represented by three distinct classes. The next few paragraphs will explain the terms used in this system of classification. Actuation of a contact mine takes place only when a target ship actually touches the mine or one of its sensitive components. The required contact point may be the mine case, a horn, an antenna, a snag line, or a protruding arm, depending on the particular characteristics of the mine involved. Contact firing mechanisms may be further classified as electrochemical, galvanic, or mechanical. Electrochemical contact mines have fragile protruding horns, each one of which contains a glass vial of acid. When any horn is struck forcibly, its vial breaks. Then the acid supplies the electrolyte to the plates of a battery cell that generates sufficient current to fire the detonator. The galvanic type of contact firing mechanism employs the current drawn from a sea battery formed by the immersion of two dissimilar metals in sea water (a weak electrolyte) to fire the mine. The metals normally used are copper and steel. The copper is in the firing mechanism; the steel is either in the target hull or in a mine component that requires a blow from a target hull to place it in a closed electrical system with the copper. The earliest galvanic contact devices were horns assembled to the mine case. In the Mark 6 type of moored contact mine, the contact area of this type of firing mechanism has been increased considerably by the addition of an antenna or sometimes a pair of antennas, the second of which doubles as the upper part of the mooring cable. Horns on the float that streams the upper antenna also act as contact devices. The mechanical type of contact firing mechanism is usually triggered by the inertia of impact, or by the mechanical movement of a protruding horn, arm, or bridle. The contact area of this type of mechanism is sometimes increased by the use of snag lines. Mechanical-type firing mechanisms are not extensively used by the United States Navy. The nearby presence of a ship, rather than actual contact, is all that is necessary, under certain conditions, to actuate an influence mine. The three classes of influence firing mechanisms are the magnetic, acoustic, and pressure types. The actuating influence in a magnetic firing mechanism is the magnetic effect of a cruising steel ship. The acoustic mechanism responds to the underwater sound waves set in motion by the normal noises of a cruising ship. A ship in motion creates an area of reduced or negative underwater pressure, to which the pressure mechanism responds. In actual practice, a number of mines contain 2 of the 3 types of influence devices. Others may contain an influence feature and a contact one. If contact or influence features are combined with a control feature, the two may be independent of each other, or control may be exercised to render a given mine safe or dangerous at the will of the control station. 13A3. Major components The major components of a mine are the case, the explosive filler, the anchor (if one is used), and the firing mechanism with its accessories. The mine case provides a watertight compartment for the main charge and the firing mechanisms. The main charge is cast into the main compartment, and for bottom mines will fill most of it. For moored or drifting mines, the case must be large enough to provide the proper amount of air space for buoyancy. Smaller compartments within the case house and secure the batteries, firing mechanism, and various accessories. Mine cases are usually made of steel, but a nonferrous metal is required when certain influence firing mechanisms are to be used. Anchors for the various moored mines naturally differ in size, shape, and method of operation. All must be capable of mooring the mine at a preset depth below the surface. For ease in handling, the anchor is assembled integrally with the case. Aircraft- and submarine-laid moored mines have the anchor secured firmly enough to the case to allow the mine to be lifted by either end or by a strap in the middle. |

|

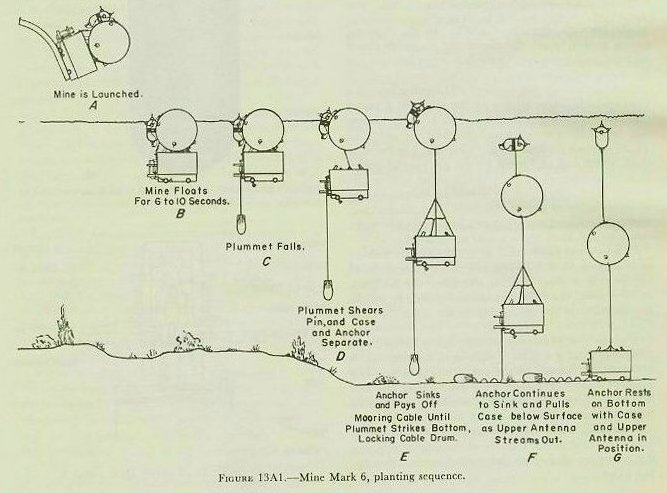

| The operation of the anchor assemblies during planting of a typical moored mine is illustrated in figure 13A1. Note that this surface-laid assembly has a net positive buoyancy until the mine and case are separated, flooding the anchor. Conversely, aircraft-laid or submarine-laid assemblies, which are employed in offensive mining operations in enemy waters, have a net negative buoyancy and never reach the surface after planting. The submarine-laid assemblies sink to a minimum depth of 65 feet, and further incorporate a few seconds of delay before separation of case and anchor. Most of the standard naval mine cases will accommodate a choice of explosive fillers and a choice of the various firing mechanisms and accessories. Because of this, the mark designation of the mine usually applies only to the assembled case and anchor. On the other hand, a specific modification of a production mine usually designates its explosive filler, firing mechanism, accessories, and the special features which adapt this mine to surface, submarine, or aircraft planting. 13A4. Accessories The accessories of a mine include a number of units which assist or modify the action of the actual firing mechanism. For example, there are the batteries which furnish the power for the operation of the mine. Some of the accessories are safety devices, while others serve to increase the efficiency of the planted mine. 1. An extender is a hydrostatically operated device used to move the mine’s detonator into a booster charge. Until the mine has been planted, the extender holds the detonator sufficiently clear of the booster to prevent a premature firing of the detonator from exploding the booster or the mine. After the mine is planted and reaches a certain depth of water, the extender moves the detonator into an envelope in the booster. See figure 13A2. In the extender shown in this figure, the piston rod transmits linear movement of the piston to the lazy-tongs linkage that moves the detonator. |

|

|

|

| 2. A clock delay mechanism (CD mechanism) is a device which delays arming of the mine for a preset time after planting. It is basically a spring driven cam that operates electrical contacts or switches. There are two distinct types. One is a hand-wound clock which can be started by the mechanical action of a hydrostatic clock starter; the other is a motor-wound clock which can be started by closure of one of the switches of the hand-wound clock which must always be used with it. Figure 13A3 shows where the extender and clock mechanisms are located. Hand-wound clocks may be set to provide a delay in arming of 1/2 to 10 days, and motor-wound clocks can provide a delay of 3 to 100 days. In addition, motor-wound clocks have a sterilizing switch, which, if utilized, ends the armed life of the mine 3 to 210 days from the time of planting. The clock delay employs at least two switches in the process of arming a mine. Closing of the first switch connects the battery to the firing mechanism. The second switch closes 3 or more hours after the first one, to complete the circuit from the firing mechanism to the detonator. 3. A clock starter (CS mechanism) is a hydrostatically operated device capable of starting or stopping the operation of a clock delay mechanism. See figure 13A4. Both clock starters and the extender mechanism mentioned earlier employ some positive type of safety device to prevent their operating prematurely. For surface-laid mines, this usually consists of a soluble washer which prevents a spindle attached to the hydrostatic piston from moving inward until the washer has been dissolved by the sea water. Aircraft-laid mines employ an arming wire which must be pulled free of the mechanism. Submarine mines have a positive-locking safety bar which falls free when the mine is ejected from a torpedo tube. They also have a lock-ball safety device which prevents movement of the hydrostatic piston until sufficient depth is reached. For further safety in handling and stowage, safety nuts are always provided to keep extenders and clock starters in the unarmed condition. These safety nuts must be removed before planting, or the mine will not arm. 4. An anticountermining device (AC) is sometimes used to deaden the mine’s electrical circuits for a short time following a nearby shock or explosion. 5. Batteries used in a mine must provide the voltages and power to operate the firing mechanism and set off the detonator. All naval mine batteries are of the dry-cell type, each composed of several cells arranged in a housing. The life of the batteries in a planted mine is what largely determines the life of the mine itself. 6. A sterilizer (SD, for self-destructive, mechanism) is used to limit the armed life of a mine to a predetermined period. At the end of this time it operates, usually to short out the battery. In some instances it may open the detonator circuit. In the case of a moored mine, it may function to fire a sinking detonator which blows out a plug and permits water to enter the case. Sterilizing switches are sometimes incorporated in a clock delay mechanism. However, the most positive type of sterilizer consists of an electrolytic cell, a resistor, a spring-loaded plunger, and switches associated with the plunger. As current flows through the cell, the anode is electrolyzed away until it is sufficiently weakened for the plunger to rupture the cell. Movement of the plunger closes two normally open switches, shorting out the battery. When thorough sterilization of a mine field must be sure to be completed by a certain date-for example, to allow passage of our own vessels-two or more sterilizers may be connected in parallel in each mine. 7. A ship counter (SE device, formerly called a ship eliminator) is used to delay firing of the detonator until a pre-set number of complete actuations of the firing mechanism have occurred. Thus a number of ships may pass over the mine before it becomes armed. This device reduces the effectiveness of the enemy’s countermeasures, and it vastly increases the effectiveness of an offensive mine field. 8. Microphones (MI), usually of the crystal type, are used with acoustic firing mechanisms. These microphones must be watertight and extremely rugged in construction. Microphones must be particularly sensitive to sounds in the frequency range for which the associated firing mechanisms are designed. 9. A search coil (SC) is used in a magnetic influence mine to detect changes caused in the earth’s magnetic field around the mine by the magnetic field of a moving ship. A coil consists of 15,000 to 30,000 turns of fine copper wire wound over a cylindrical core of high-permeability magnetic alloy, such as permalloy. A search coil is always used with a steel mine case, because the steel adds to the effective size of the permeable core. 10. One minor accessory which adds greatly to the ease of assembling a mine and testing its various circuits is the terminal block (TB). The circuits, batteries, firing mechanisms, and various other electrical accessories are connected at this block. The block (or the main block, if the mine has more than one) is located just under the main cover leading to the firing mechanism. Thus it is readily available for final electrical tests and for connecting of the detonator leads just before the mine is sealed. 11. Many aircraft-laid mines (see section B) use some sort of flight gear to decrease the impact velocity of the mine as it strikes the water. This usually consists of a parachute, parachute pack, and release gear. As the mine strikes the water, the release gear operates, freeing the parachute from the mine case. Parachute and mine will sink free of one another. |

| 13A5. Representative firing mechanisms Firing mechanisms are the units which are set off by contact with a target ship or which, alternatively, receive a small impulse from the search coil, microphone, or pressure device and send a magnified firing impulse to the detonator. Newer and better firing mechanisms are constantly being designed. The mechanism must, of course, fire the mine when a bona fide target goes by. That in itself is simply a problem of amplifying the original signal to an impulse strong enough to trigger the firing, circuit. The reason firing mechanisms are so complicated in construction is that they are designed in such a way as to avoid actuation by countermeasures such as minesweeping by the enemy. Section A of this chapter described contact firing mechanisms in enough detail for the purposes of this course. Influence mechanisms, being more complex, need a somewhat more detailed discussion. The next few paragraphs will take up the three classes of influence mechanisms-namely, the magnetic, acoustic, and pressure types. 1. Magnetic mechanisms. Every steel ship has definite magnetic characteristics produced by the permanent magnetism of the ship’s hull and the induced magnetism resulting from passage through the earth’s magnetic field. A ship’s magnetic field may be reduced substantially by using degaussing coils, often in conjunction with the process of deperming (neutralizing the permanent magnetism of a ship); but for practical and theoretical reasons it is impossible to eliminate such fields entirely from ships of even moderate size. Magnetic mine-firing devices are of two general types: magnetic dip-needle and induction. The actuating unit of the needle-type mechanism is a magnetized needle assembly which responds to changes produced in the vertical component of the earth’s magnetic field by the proximity of a ship. Once the mine is planted, a very slight movement of the needle may trigger the firing circuit. The induction-type mechanisms employ a search coil and a means of amplifying the signal from the search coil. Some induction mechanisms use a sensitive relay for this purpose. Others have a highly complicated electronic or electronic-mechanical system. From the above, it will be noted that the needle-type mechanism operates simply upon the magnitude of change in the magnetic field, whereas mechanisms of the induction type may require both magnitude of change and rate of change, two or more actuating pulses (called looks) of opposite polarity, or other special conditions. This feature gives the induction mechanism a distinct practical advantage by allowing a wider diversity of selective firing. Induction firing mechanisms can be used in mines with ferromagnetic cases, while needle mechanisms require mine cases of nonmagnetic material (usually aluminum). Induction mines can be made much more sensitive than needle mines. 2. Acoustic mechanisms. Acoustic disturbances such as propeller noises, machinery noises, and hull vibration invariably accompany the passage of a ship through the water. The output depends upon several factors such as size, type, and number of propellers, type and speed of engines, condition of loading, character of the bottom, and depth of water. A ship’s acoustic signal is therefore variable, and acoustic mines must be designed in such a way as to prevent an intense signal from actuating the firing mechanism at distances well beyond the effective explosive radius of the charge. Acoustic mines must also be unresponsive to types of underwater sounds that are likely to represent non-target objects-such, for example, as a school of porpoises. Another design requirement is that these mines must not be easily actuated by countermining noises. Therefore acoustic mines are usually fired by actuating the mechanism when the sound intensity reaches a predetermined value, after building up at a prescribed rate of change. If the incoming sound builds up too quickly, as in the case of an underwater explosion, the mine will inhibit itself from firing by the action of an anticountermining device, and will become passive for a short time. If the sound builds up too slowly, the mine will not respond at all. The United States Navy has no distinctive acoustic mine, but employs acoustic firing mechanisms as accessories which are designed to be interchangeable with other firing devices in several different mine cases. 3. Pressure mechanisms. There is a continuous flow of water from the bow to the stern of a moving ship. As the forward part of the moving ship displaces water, an equal amount must flow to the after part of the ship to restore the displaced water after the ship has passed. This continuous water flow is measurable at considerable distances from the ship, and creates variations in the pressures which normally exist at various depths in the water. The pressure differential becomes more pronounced when the ship is moving in confined waters, such as rivers, but is still appreciable in the open sea, even at considerable depth. The pressure signature of a ship is a function of its speed and displacement and the water depth. Ocean swells and surface waves also produce pressure variations of considerable magnitude; but in a much faster cycle than those of ships. Therefore, to avoid premature firing because of wave action, pressure firing mechanisms are designed to ignore rapid pressure fluctuations. Pressure firing mechanisms are seldom used alone, but are generally combined with other influence firing devices. 13A6. Special-purpose mines Special-purpose mines are those designed for special missions. A self-propelled torpedo mine-also called a mobile mine-permits a submarine to lay mines in water too shallow for safe navigation of the submarine. This mine becomes a bottom influence mine at the end of its run. The delayed-rising mine is used in offensive moored fields. This mine lies on the bottom, married to its anchor, until the mine case is released either by the functioning of a time delay or by a ship-counting mechanism. The case then rises to set depth. Moored antisweep mines are interspersed in moored-mine fields. Antisweep mines are designed to explode and destroy sweep wires when such wires strike the mooring cable or float. Examples of other special-purpose mines are limpet mines and beach-defense mines. The latter are bottom mines laid in shallow water and designed to explode on contact with landing craft. |